Brief Introduction:

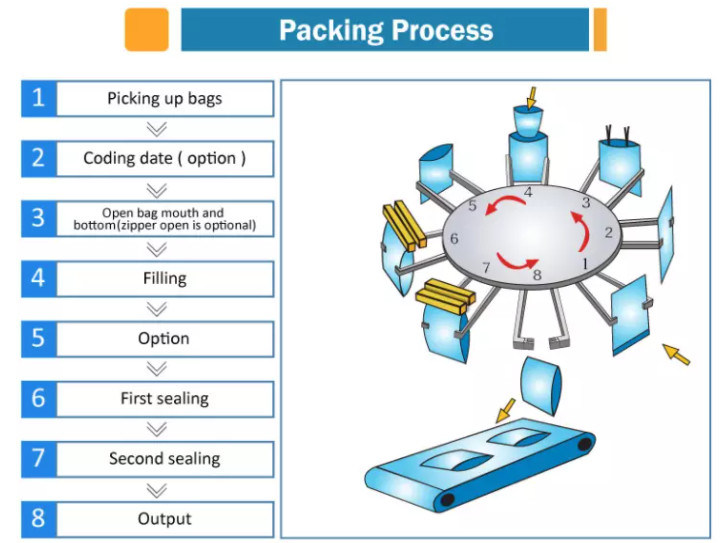

Rotary premade bag packing machine with different dosing (such as multihead weigher, auger filler, liquid filler etc.) can be suitable for the automatic packing for granular, powder, liquid, paste etc. The machine can realize automatic pouch feeding, date printing, bag opening, material weighing filling, bag heat sealing and finished bag take-off. Mest Machinery have different models for your reference depending on the packing material and bag size.

Features:

- Heat sealable premade flat pouch dosing and sealing.

- PLC & HMI Control, easy for parameter setting and troubleshooting.

- Different pouch size adaption, simple adjustment without tools.

- Intelligent temperature controlling configuration, ensure the artistic and neat sealing.

- Skip steps of filling and sealing if failed hold, or bag failed open.

- Compatible Programs of powder, granule or liquid dosing, plug and play, easy for different products switching.

- Machine stopping interlock with door opening.

Safety Device:

- Skip the step of filling if the failed hold, or bag failed open.

- Skip the step of sealing if the failed hold, or failed filling.

- Emergency stop and alarm if the coding ribbon used up.

- Alarm if the safety door door is opened (option).

- Alarm if the air pressure is used up.

- Alarm if the seal temperature anomaly.

Application:

- Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc.

- Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer.

- Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc.

- Liquid / paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste.

- Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc.

- Other bagging materials.

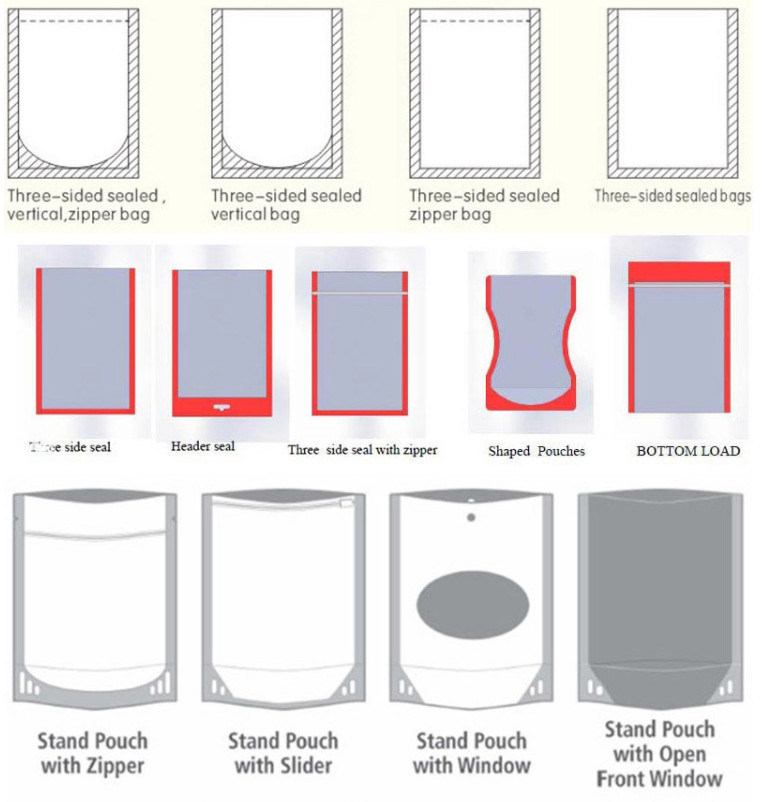

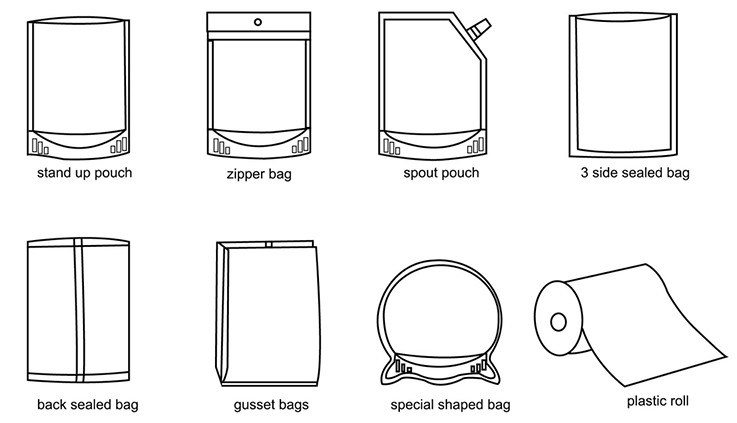

Different Premade Pouches:

Stand up pouch, stand up pouch with spout, Doypack pouch, Gusset stand up pouch with zipper, 4-side sealing pouch, Zipper pouch, etc premade pouches ect.

Technicial Parameter:

| Model | MST-200B | MST-300B |

| Number of working position | 8 (6 station is customizable) | |

| Metering range | 5g-1500g | 100g-2500g |

| Accuracy | ≥99% | ≥99% |

| Speed | 10-50bags/min | 10-40bags/min |

| Bag width | 100-210mm | 200-300mm |

| Bag length | 100-350mm | 200-450mm |

| Air consumption | 0.6m3/min 0.65Mpa | 0.6m3/min 0.65Mpa |

| Voltage | AC 3-phase 380v 50/60HZ | |

| Power | 1.5Kw | 2Kw |

| Dimension | 1650*1380*1500mm | 2200*1850*1500mm |

| Weight | 1060Kg | 1280Kg |

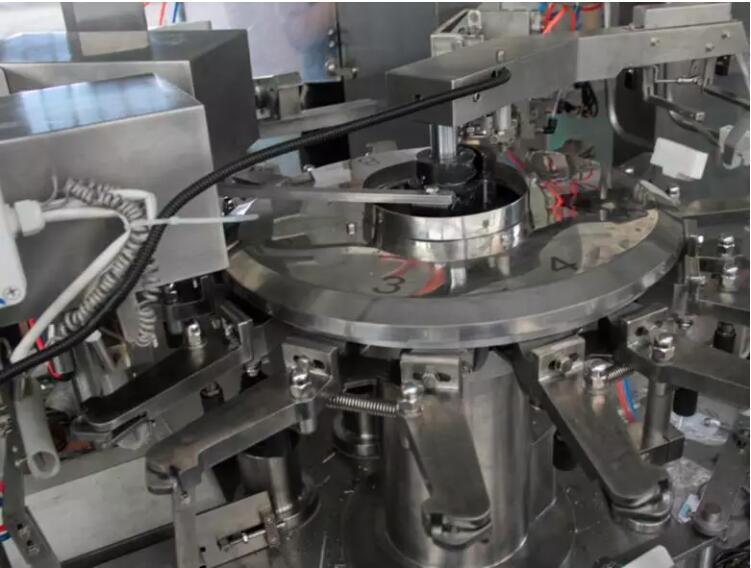

Machine Pictures:

Parts of Finished Packing Sample:

FAQ:

- Q: Are you trading company or manufacturer ?

- A: We are manufacturer since 2001.

- As the same of most manufacturers, we first carry out domestic trade, and registered Alibaba (Chinese Trade) in 2005.

- Q: What's the guarantee of the machine?

- A: We have 2 year's guarantee of the machine

We would like to send you new one since we have one year warranty. You also can buy from your market if more convenient. And we will take videos and pictures to teach you how to replace it.

Engineers available to service machinery overseas. (You need to pay tickets, food, hotel and salary), but anyway it's up to you. But according to my experience, there's nearly no wearing parts.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: How to install the machine after we received the machine?

A: When you received the machine, just connect it with electric and air compressor then can run it. (It will cost a little more if you need our team to your place (you need to pay tickets, food, hotel and salary), but anyway it's up to you. We'll test the machine and make sure the machine runs well before shipment. (We'll send the testing video for your checking)